Engineering

We can support you in many aspects of the development of a roll forming line. From process development to simulations and pilot production, we can help you competently.

Plant control

The decisive interface for the interaction between man and machine is the human-machine interface (HMI). As experienced rollformers, we also consistently think about our control concepts from the user’s point of view. Modern sensor technology and process support are fundamental principles of this way of thinking. To this end, we master the interfaces with both Siemens-based and Bosch-Rexroth controllers.

With our intuitive Human-Machine-Interface (HMI) you get the advantages of modern digitality for easy usability and highest functionality. The customer-specific applications and processes can be optionally added – simply like apps.

The software coordinates all relevant production parameters. It provides real-time information on all plant parameters clearly displayed on a monitor:

- Evaluation of production processes and process parameters

- Management of product variants such as hole patterns and length variants

- integrated quality inspection

Because in the end, the profiles will be as good as the perfect synergy of man and machine. That is smart profiling!

Data Management

Production data serve many companies as a basis for important decisions and help to upgrade a wide variety of processes. The data dashboard meets all Industry 4.0 requirements.

It includes the clear display of warning and error and status messages and provides an overview of upcoming scheduled maintenance. Furthermore, the traceability of program changes plays a central role and the notification function enables shortest response times and a fast transfer of diagnostic data to remote support & troubleshooting. We help you harvest this data and process it profitably.

Your advantages

- Open interfaces for your internal IT connection such as BDE or ERP systems

- Visualization of the condition information

- Future viability also for existing systems

Test execution, sample parts and pilot series production

We accompany you on this path and, in cooperation with our partners, can offer you a manageable time horizon until you have the first components of your new products in your hands. In this context, we also support you in carrying out trials and testing your components until they are released. We are happy to validate our simulations in practical test runs so that no questions remain unanswered.

Your advantages

- Bridging delivery times through rapid pilot series production

- Provision of sample components and support during testing

- Conducting experiments to clarify open questions

Project Management

Turn-key projects are a convenient path to productivity. From 40 years of contract profiling and plant engineering, we understand your needs for speed, quality and efficiency.

We are happy to support you with goal-oriented project management or as a general contractor with overall responsibility as a reliable partner at your side. Contact us and together we will find a “turnkey” machine solution.

Your advantages

- Access to experienced project managers as project facilitators

- Turnkey plants and uncomplicated commissioning

- Reliable contact for all matters concerning your project

Process development

Method planning in forming production is crucial for the economic success of your products. Expand your manufacturing possibilities with us. We will also find efficient and resource-saving rollforming solutions for you for extruded sheet products or those manufactured by manual bending. We advance your process development and provide you with a customized process layout for the manufacture of your products.

We would be happy to review your current processes with you to identify potential for optimization and increase productivity, quality, and resource efficiency.

Your advantages

- Customized process layouts for your technical processes

- Screening of optimization potentials

- New perspectives on long entrenched process flows

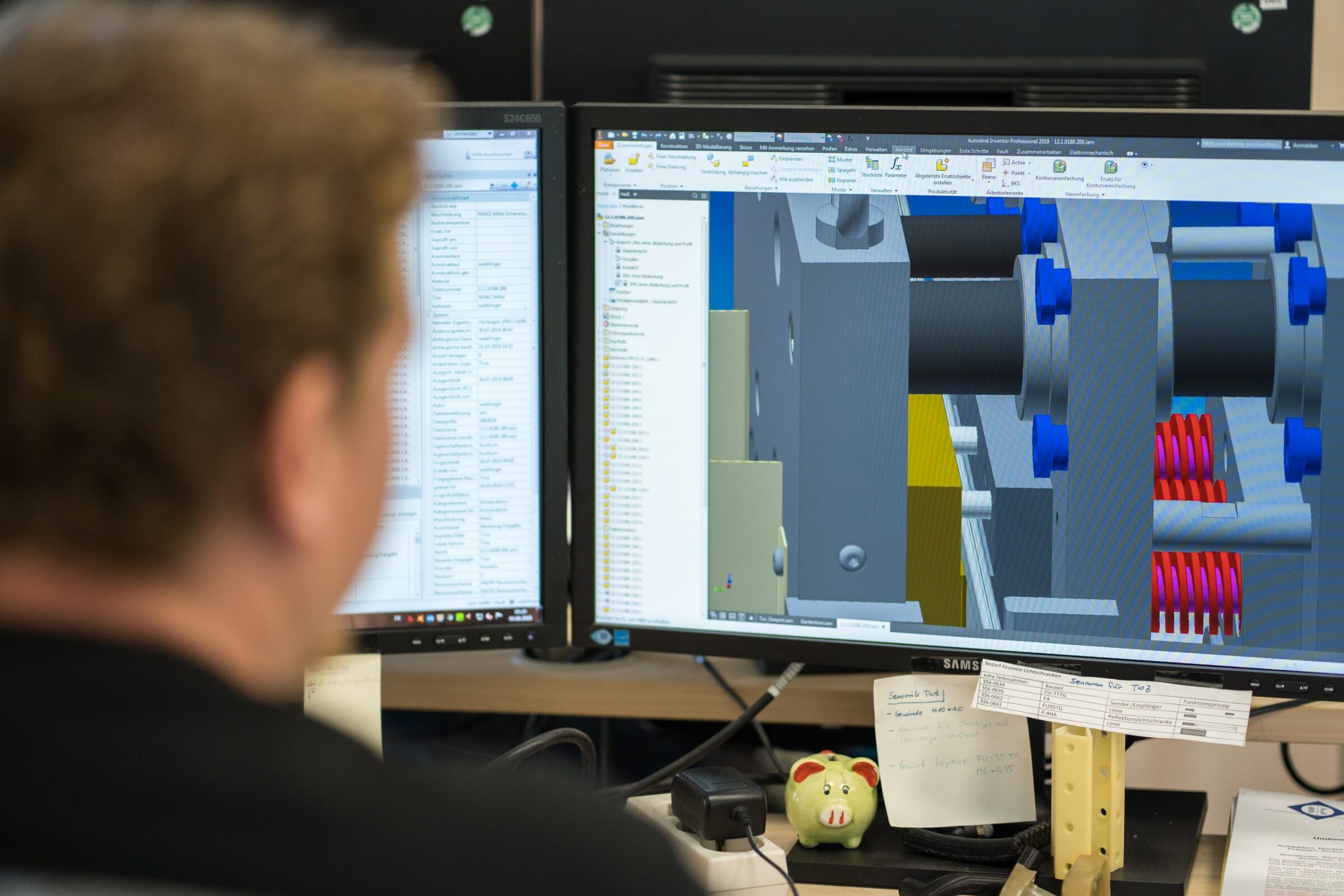

Simulations

Virtual method planning using FE simulation provides precise insights into the forming processes of your components. In addition to the analytical design of production processes, process simulation or FEA (Finite Element Analysis) complements the planning of manufacturing technology. Numerical mapping of the forming processes taking place provides detailed insights into the material-technical conditions by evaluating stress diagrams, strains or, for example, targeted sheet thinning.

For process simulation, Profilmetall Engineering has the most modern analysis tools and the corresponding expertise at your disposal. From forming simulation from the coil to the manufactured profile or a load simulation of the finished component (component and product simulation), we will be happy to calculate and analyze the answer to your questions.

Your advantages

- Insight into the basics of forming technology without complex experimental setups

- Support for virtual method planning

- Reliable statements on the manufacturability and feasibility of your products

Technology Consulting

With the combined expertise of over 40 years of contract roll forming and roll forming line construction, we can advise you on many issues related to your roll formed components.

In feasibility analyses, we provide advice and assistance in the process design of production processes as well as process selection. We are happy to start with you already at the product design stage, but we will also gladly take care of setup time optimization and automation of your production processes in order to implement an increase in productivity. Repeat quality and tool life optimization are not neglected in this process. Benefit from our process and design consulting and contact us.

Your advantages

- Support in process design from planning to implementation

- Feasibility studies and technology consulting for your individual components

- Optimization and automation of your existing plants

Tools

The roll-formed profile is as good as the forming tool used to produce it. As a machine manufacturer and user of a wide variety of technologies, we see our tools from different perspectives and can perfectly analyze and understand the needs. That is why we place the highest value on the quality of our tooling systems and components.

In the Technology section you can see the variety of processes for which we offer tools such as roll forming tools, punching tools, cutting tools and profiling tools. The systems can be seamlessly integrated into our equipment as well as the control system and offer all users the best possible convenience.

Your advantages

- Design and manufacture of tools and tool systems according to your requirements

- Commissioning and testing of the tools

- Tool development for special processes